Complete aerostructure, propulsion, electronics, and control system engineering for UAVs and rocket systems.

Design & Engineering

Design with Engineers

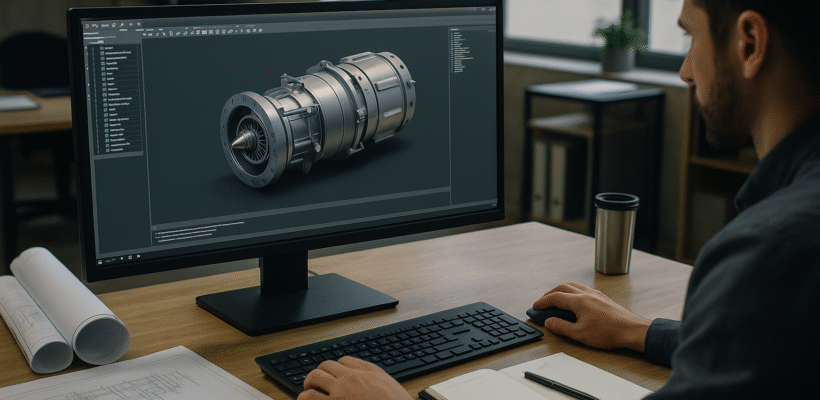

Our Design & Engineering team transforms mission requirements into high-performance UAV and loitering-munitions systems. From aerostructure modeling to propulsion integration and electronics architecture, we follow a disciplined engineering workflow built for Défense-grade reliability.

CAD & simulation

We use advanced CAD, simulation, and rapid-prototyping tools to evaluate airframe concepts, optimize aerodynamics, and validate structural performance before field testing. Every component — from control surfaces to onboard electronics — is engineered for precision, durability, and modularity.

Our Design & Engineering process is supported by disciplined project scheduling and management to ensure every development milestone is met with precision and accountability. We use structured workflows—covering design reviews, prototyping cycles, testing phases, and integration checkpoints—to keep the project on track from concept to deployment.

Our team follows a transparent planning framework that includes:

- Clear milestone definitions for design, prototype, testing, and validation

- Agile development cycles for rapid iteration and improvement

- Risk assessment & mitigation planning to avoid delays

- Resource allocation & timeline optimization for efficient execution

- Weekly progress reporting for complete visibility

- Cross-team synchronization between hardware, software, and testing units

With robust planning tools and defence-grade documentation practices, we ensure your UAV or mission-critical system progresses smoothly through every engineering stage—on time, on specification, and ready for field evaluation.

Our Value Engineering process ensures every component of your UAV or mission-critical system delivers maximum performance at the lowest possible lifecycle cost—without compromising safety, reliability, or mission capability.

We analyze the complete design—from airframe geometry to electronics, propulsion, fabrication methods, and software architecture—to identify opportunities for:

- Cost Reduction: optimizing materials, components, and manufacturing methods

- Performance Enhancement: improving aerodynamics, endurance, and system efficiency

- Weight Optimization: reducing mass without impacting structural integrity

- Modular Design: enabling easier maintenance, faster upgrades, and simplified logistics

- Component Rationalization: eliminating unnecessary parts and reducing assembly complexity

- Manufacturing Efficiency: shifting to processes that lower production time and cost

Using a structured approach (FAST diagrams, function analysis, cost–benefit modelling, and prototype benchmarking), our engineering team enhances mission performance while improving overall product value.

The result is a more efficient, lighter, and cost-effective UAV system—engineered for reliable field deployment and scalable production.